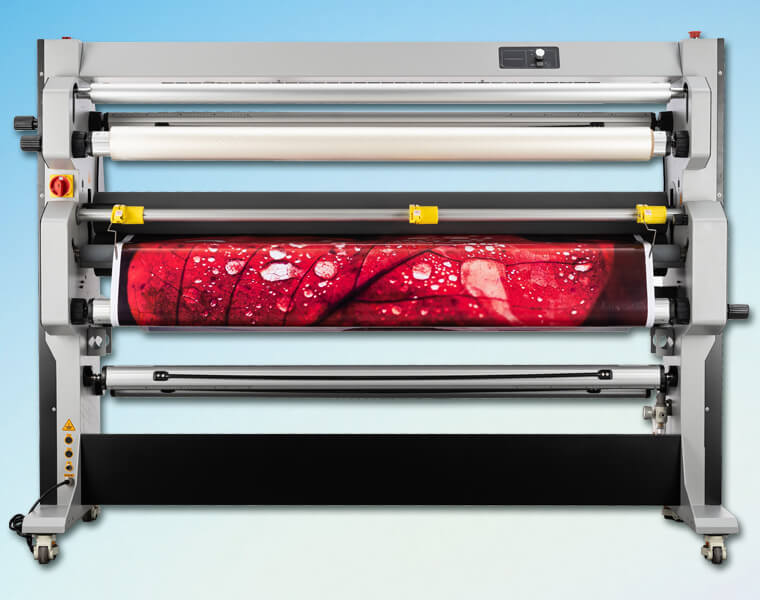

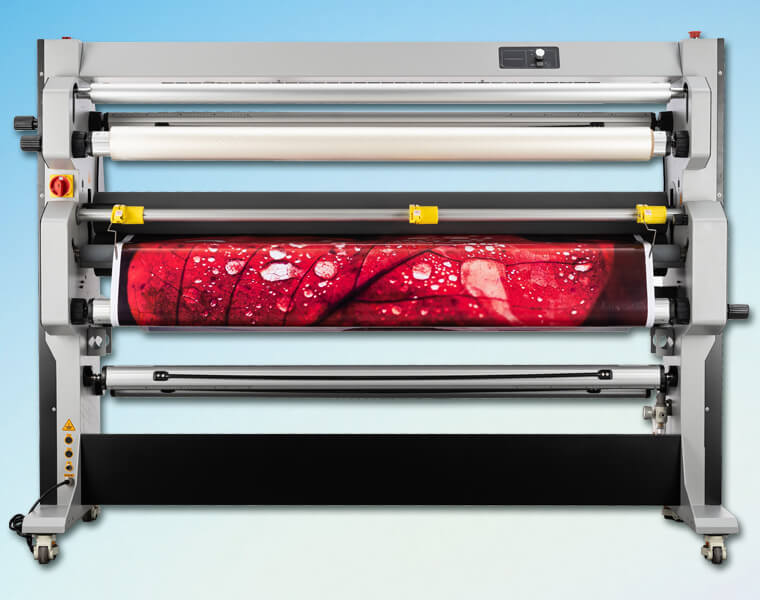

Model: LF1700-D2 Pro Double Sides Laminator

Rear Trimmer: 3 Pcs

Max Lamination Width: 1630mm/64″

Lamination Temp: 0~60°C/0~140°F (0~120°C/0~248°F Optional)

Max Lamination Speed: 28 M/Minute

Roller Up and Down: Pneumatic Pressure

|

Model |

LF1700-D2 Pro Double Sides Laminator |

LF1700-D2 Pro Double Sides Laminator |

|

Lamination Type

|

Warm & Cold

|

Hot & Cold

|

|

Lamination Temp |

0~60°C/0~140°F |

0~120°C/0~248°F |

|

Cutters |

≥3 Sets |

|

|

Laminating Type |

Roll-to-Roll |

|

|

Heating Roller |

Top (Double Sides Lamination Optional) |

|

|

Max Lamination Speed |

28 M/Minute |

|

|

Max Lamination Thickness |

28mm/1.1'' |

|

|

Max Lamination Width

|

1630mm/64''

|

|

|

Roller |

Silicon |

|

|

Diameter of Roller |

130mm |

|

|

Pressure/Height Adjust |

Automatic (Pneumatic Pressure) |

|

|

Hand Protection Device |

Safety Laser Sensor |

|

|

Anti Static Electricity |

Yes |

|

|

Certificate |

CE, RCM, ROHS |

|

|

Hand Safety Sensor

|

Yes

|

|

|

Heating |

Infrared |

|

|

Preheating Time |

10-15 min |

|

|

Voltage

|

110V/220V 50/60Hz

|

|

|

Package Size

|

2270*810*1660mm=3.1CBM (Including Air Compressor)

|

|

|

Gross Weight |

370KGS |

|